Packaging integration and automation

A team of experts from Bosky supports you to the maximum extent during the implementation of projects, from the first conversation with a consultant to our experienced and professional after-sales service. Both small and large companies benefit from our many years of experience in integrating and automating processes from the dosing and weighing stage, to individual packaging, marking, quality control, cartoning, palletizing and securing products on pallets for transport.

.

We offer comprehensive solutions for many industries and market sectors

As a supplier of individual and comprehensive solutions, we have extensive competences in the field of automation of selected sections and complete production lines, we focus on the optimal and efficient integration of all functions related to the packaging process and the subsequent ones.

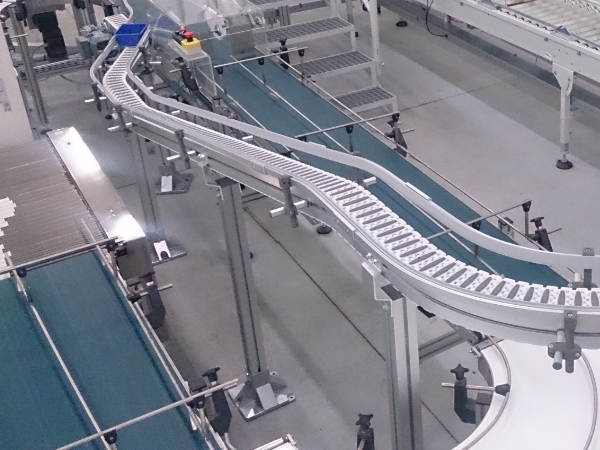

In addition to designing complete lines, we also offer the possibility of integrating standard machines and parts of technological lines prepared according to individual customer requirements, free-standing robotic stations or the ones incorporated into existing production lines, and other various variants complementing technological lines, implemented in semi-automatic stations variants – in which employees can use tools and machines. These solutions may include full sets of machines, technological stations or conveyors, performing all process activities programmed in the technological line system.

Bosky’s offer covers comprehensive solutions for many industries and market sectors.

Each production line is an extraordinary and unique order for us. We approach each new project individually, starting work with a detailed interview with the client and familiarizing with his needs, completing technological and product specifications, product analysis and the designated place/location, production environment and used technologies. On the basis of complete data we prepare an optimal solution. Then, depending on the requirements of a given project, at the stage of investment valuation and on the basis of an on-site verification and technical consulting, we analyze different variants. Based on our analyzes and arrangements with the client and sub-suppliers, we prepare a comprehensive technological line design with a budget offer, including, among others descriptions of machines, equipment included in the solution and processes, analysis of cycle times and other data and conditions, and, if necessary, also an analysis of the profitability of the project.

We have many years of experience and a wide portfolio in the field of automation of packaging processes.

What will you gain?

Examples of the benefits of automation:

- increase in process efficiency

- greater production efficiency

- lower costs of processes handling

- lower labor costs

- improvement of work ergonomics

- improvement of product quality

- reduction of production waste

- elimination of production downtime

- development of the enterprise

Wydajność linii 60 palet/h – projekt zrealizowany dla koncernu logistycznego

Automatyzacja procesu paletyzacji, wiązania z nakładaniem narożników i owijania gotowych palet.

Wydajność linii 64 kartony / minutę, 50 palet/h – projekt zrealizowany dla jednej z największych firm polskich sektora Agri

Automatyzacja procesu paletyzacji i owijania gotowych palet.

Wydajność linii 25 palet/h – projekt zrealizowany dla państwowej spółki cukrowniczej

Automatyzacja procesu spinania opakowań wielkogabarytowych.

Wydajność linii 40 opakowań/minutę – projekt zrealizowany dla czołowego producenta rowerów

Automatyzacja ważenia i pakowania w pojemniki produktów baby leafs (rukola, roszponka, itp.).

Wydajność linii 80 pojemników (250g)/minutę – projekt zrealizowany dla największej Polski firmy i dostawcy sałat i warzyw – sektora Agri

Automatyzacja wiązania w pionie specjalistycznych kontenerów na wózkach transportowych.

Specjalistyczna stacja wiązania dostarczona dla czołowej firmy sektora automotive

Comprehensive projects executed out by our team are a guarantee of efficiency, high quality and perfect preparation.

Thanks to our help, your production will gain a solid, technologically advanced face, the plant’s operation will become more efficient, and the quality of

the process and the precision of the tasks will increase. All this translates into investment satisfaction.

Please contact us, our team is not afraid of challenges!